PREDICTIVE ROBOT SOLUTIONS AND TAKEAWAYS FROM AUTOMATE 2019

APRIL 29, 2019

Predictronics had a successful experience exhibiting at Automate 2019.

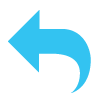

For this event, we joined forces with our business partner, Advantech, a worldwide leader in Industry 4.0, IoT systems, and industrial automation, to present a platform that merges Advantech’s data acquisition hardware and edge computing with the capabilities of Predictronics’ Factory Sentinel software.

Industrial robot manufacturers sometimes create their own solutions, which can often make data collection from the OEM controller a closed avenue.

Factory Sentinel is a packaged software solution that analyzes data acquired from industrial robots that perform repetitive functions in order to ensure high accuracy and to predict and prevent hard failures and machine downtime.

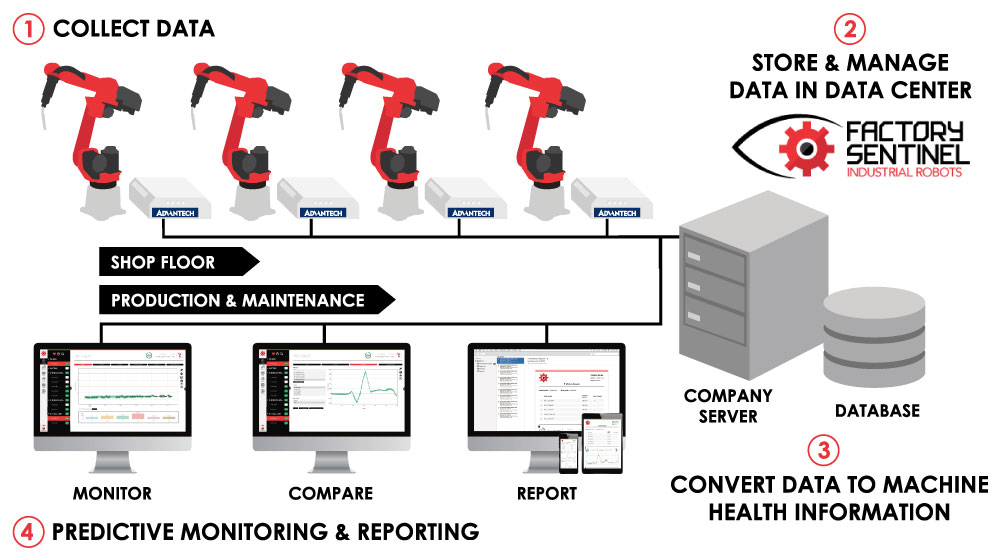

In this integrated platform with Advantech hardware, it is possible to convert the analog data from clamp current transducers within the controller cabinet of robot axis joints into a digital format, which is then fed to Factory Sentinel for data analysis and failure predictions. Not only is the transducer hardware in-expensive and non-intrusive, but the cost is further minimized by grouping multiple industrial robots with a single hardware device. The overall result is a cost-effective solution with a quick and proven ROI.

This demo collaboration showcased the intuitive interface and data visualization capabilities of Factory Sentinel while also highlighting the value it brings to real-world applications.

Beyond this platform, Predictronics has developed Factory Sentinel solutions for numerous clients within the automotive industry.

| CUSTOMER DESCRIPTION | TYPE OF FAILURE | COMMENTS |

|---|---|---|

| Customer A - Automotive Factory | Factory Motor Brake (Axis 5) - Position Accuracy Issue | This was a blind trial. They replaced the robot's axis 5 motor with a bad motor to test our algorithm. |

| Customer A - Automotive Factory | Degraded Motor Brake (Axis 5) - Position Accuracy Issue (Long Term Trend) | This robot had a long term trend and the motor brake was degraded. It would have eventually caused collisions. |

| Customer B - Automotive Factory | Grease in J3 Purged (Gearbox Issue) | This problem had a clear trend. |

| Customer B - Automotive Factory | Axis 3 (Motor Brake Failure) | Detection was possible 1-2 weeks ahead of time. |

Automate is a biannual event that serves as a meeting place for industry giants and technology providers to gather and share the latest in robotics, automation and technology solutions.

This year’s event boasted more than 500 exhibitors and over 20,000 attendees with conference sessions that discussed topics ranging from advanced robotics in manufacturing and AI solutions to motion control components and machine learning.

Members of Predictronics share their top three takeaways from the event below:

- There is a growing market of end users within a variety of manufacturing sectors such as aerospace, automotive, and medical equipment who are utilizing industrial robots and CNC machine tools in their operations. These end user manufacturers are looking to have more transparency in their operations by collecting and monitoring data from their diverse fleet of machines. Solutions providers, such as Predictronics, should seek out new opportunities within these industries and develop a deeper understanding of these machines in order to gain insights from this data that can be used to combat equipment health and part quality issues, as well as develop newer innovations.

- Systems integrators, who select robots and equipment for companies and provide installation and on-going support services, are observing an increase in requests from manufacturers to include predictive maintenance software in an integrated technology platform. Systems integrators want to make end-to-end solutions a reality for businesses who need to deploy plug-and-play applications that provide fast real-world impact on their daily operations.

- Collaborative robots are the hot new item in automation. These robots work alongside humans to perform smaller repetitive tasks. They are not only highly intelligent, but they can easily be trained by physical techniques without custom programming. This robot popularity has created a surge in demand for robotics solutions that predict failures and help robots function at peak efficiency.

For more information and weekly updates, follow Predictronics:

Monitor your industrial robots today!

REQUEST A DEMO