Predictive Maintenance for Commercial Aircraft

Industry

Commercial aviation

Asset

Aircraft flow control valves

Goal

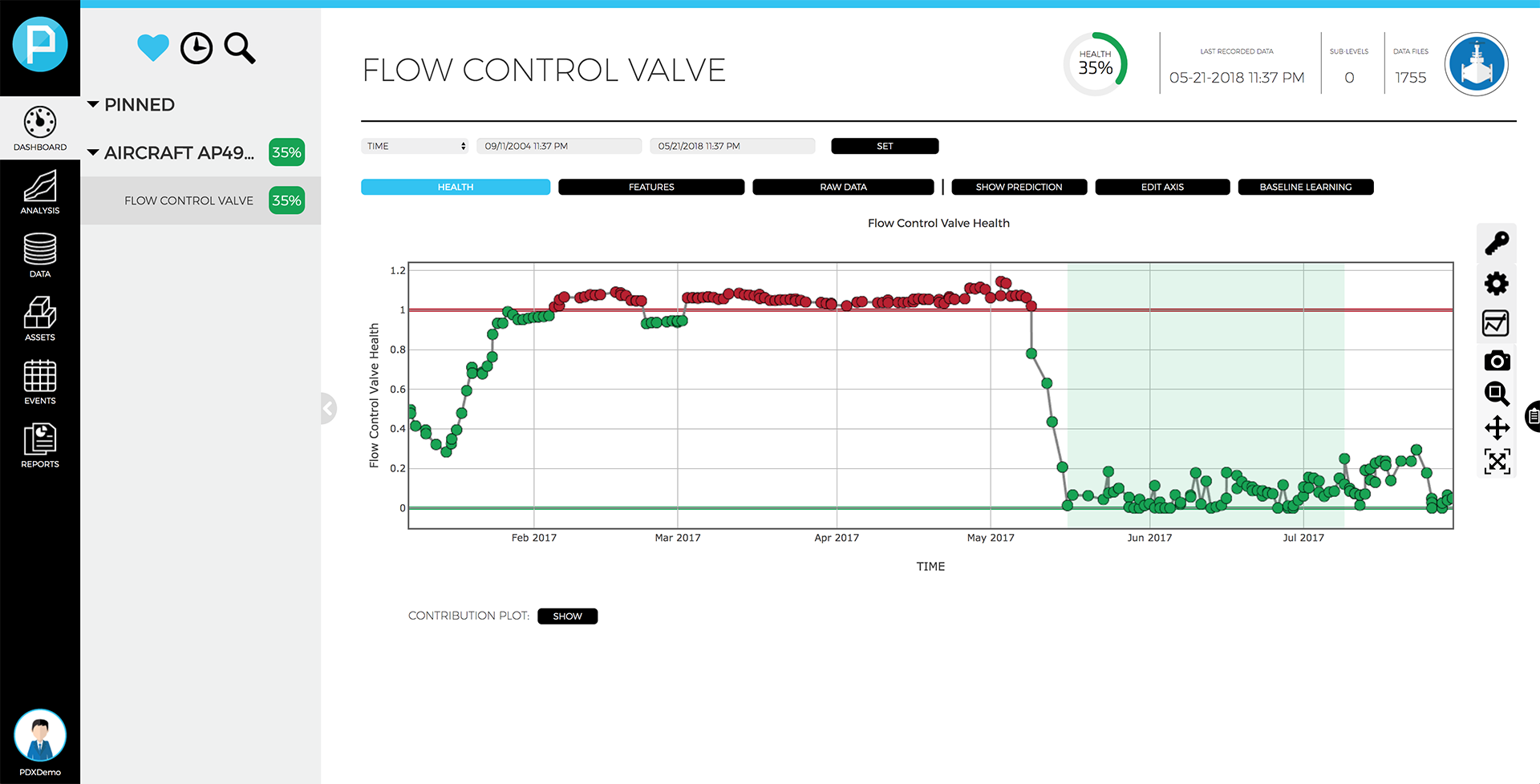

Develop a predictive maintenance solution for early detection and diagnosis of flow control valve failure

Impact

Predicted the failure of two flow control valves several months in advance and created a proactive maintenance schedule, increasing passenger satisfaction and preventing aircraft delays, which can potentially cost the airline an estimated $74.20 per minute

Overview

An international leader in commercial aviation was experiencing several flow control valve failures in their aircraft every year. Flow control valves are key components within the environmental control system of an airplane and their degradation leads to a breakdown in cabin air conditioning and air circulation. These failures cause a decrease in passenger satisfaction and an increase in maintenance costs for the airline.

Solution

The customer provided Predictronics with a year of historical full-flight data. This quick access recorder (QAR) data contained over 1,000 parameters, including in-flight operating regimes and various sensor measurements. Predictronics team members used their experience in industrial applications and statistical approaches for variable selection to identify 5-10 necessary signals from this complex data set. Through health model development and analysis, early key indicators of flow control valve degradation were detected and 5 out of 7 failure events were accurately pinpointed during the proof of concept project.

Value

By using the developed health models from historical data, the customer was able to predict two flow control valve failures several months in advance. This data-driven solution provided the airline with the evidence they needed to prioritize maintenance planning decisions and fix valve issues before they occur, improving passenger satisfaction and preventing aircraft delays, which can potentially cost the airline an estimated $74.20 per minute.