Predictive Health Monitoring of Press Machines

Industry

Automotive manufacturing

Asset

Press machine equipment

Goal

Predict potential machine failures and prevent extended downtime and unnecessary maintenance through a Predictronics software solution

Impact

Reduced scheduled maintenance by 94% and decreased production stoppage time by predicting press machine failure due to abnormal locking events up to a month before they occurred

Overview

A global Tier 1 automotive manufacturer from Japan was looking to establish a preventative maintenance schedule and avoid downtime at one of their facilities. Maintenance events were causing a decrease in net profits due to suspended production lines and increased expense from unnecessary labor and component replacement.

Solution

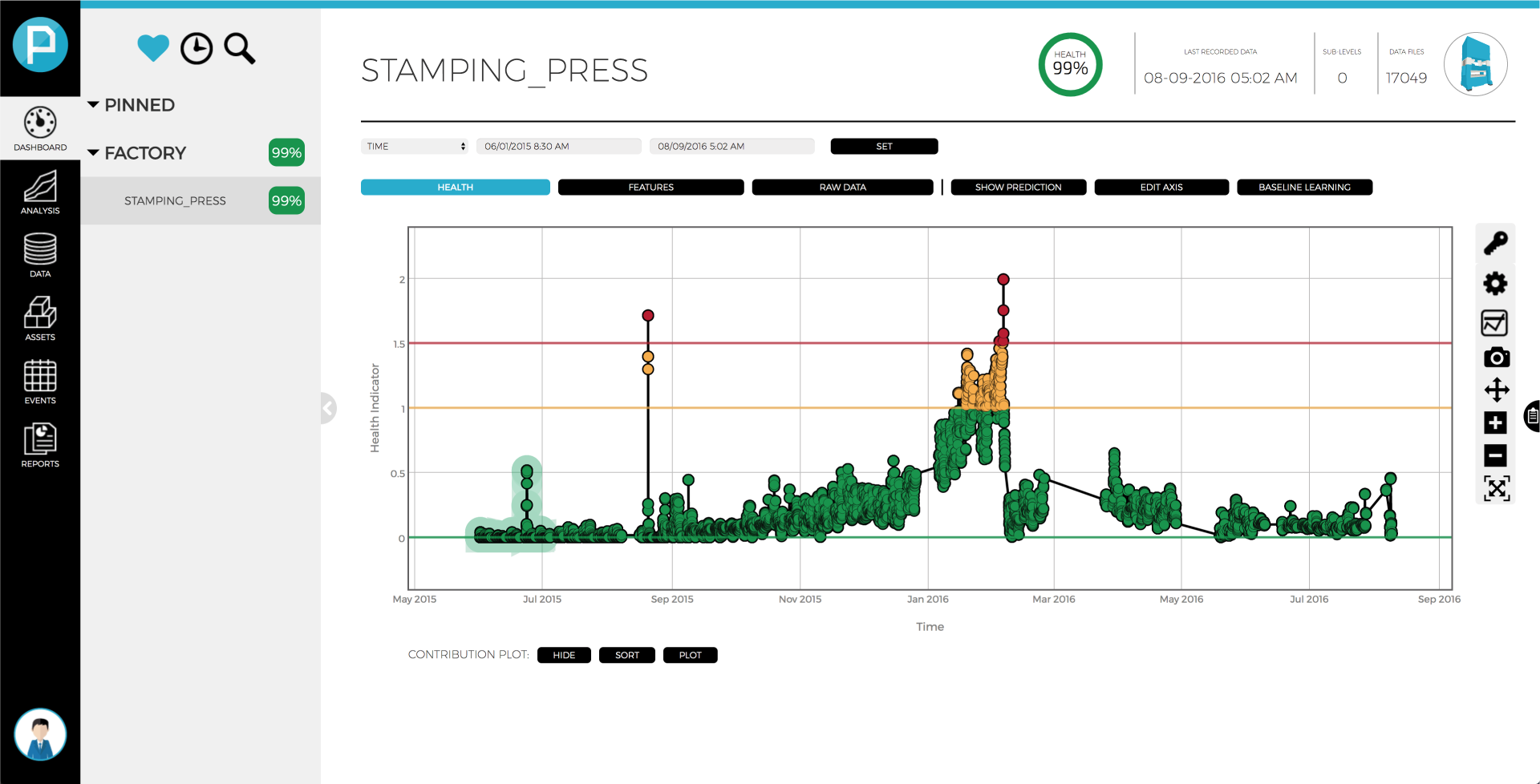

After segmenting and preprocessing the historical data and comparing it to maintenance records, Predictronics created a baseline health index and prediction models to monitor the health of components within the press machine. Our innovative approach was to identify anomalies from raw data rather than features. This particular method was more sensitive and capable of detecting more anomalies than the traditional methods. By focusing on raw data and comparing the hydraulic locking pressure to the press angle, Predictronics was able to ensure this manufacturer received the most accurate health estimates from their data.

Value

The solution provided by Predictronics pinpointed abnormal hydraulic locking pressure due to leakage as the root cause of stoppage events at the manufacturing facility. Before these findings, the customer was performing a total of thirty-five regular maintenance checks within a single calendar year. Predictronics’ analysis and predictions determined only two of these maintenance events to be necessary, reducing upkeep by 94%. This allows the company to create a more efficient data-driven maintenance schedule that saves time and resources, reduces unnecessary labor and increases profit margins.