Solving unplanned downtime, quality issues, and asset monitoring challenges through AI-based predictive analytics solutions that provide actionable data insights to drive real world impact in industrial applications.

From data collection to data visualization, our team guides customers and delivers solutions for predictive maintenance, predictive quality, and condition-based monitoring, enabled by PDX. PDX is our end-to-end software platform that monitors critical assets by collecting and analyzing big data, ensuring business impact and ROI through reduced unplanned downtime, increased productivity, optimized asset repairs, and improved product quality.

PDX for Predictive Maintenance

PDX for PdM is suited to address pain points in nearly any industry, including manufacturing, transportation, energy, industrial equipment, water, logistics, and more. This solution provides early warning of machine and/or equipment failure days, weeks, or even months in advance, allowing users to schedule maintenance for their critical assets to reduce downtime and improve productivity. PDX for PdM utilizes a template-based approach to provide pre-configured solutions that can be customized to fit a customer’s specific application, delivering faster configuration and deployment.

PDX for Condition-Based Maintenance

PDX for CBM is best suited for motors, pumps, gearboxes, fans, bearings, shafts, and other rotating equipment. This easily scalable solution utilizes low-cost sensor data to provide ‘just in time’ information for low-dollar assets, helping users know the right moment to swap out and repair their components with minimal impact on operations. Adopting PDX for CBM can also make the transition to our PdM solution more seamless.

PDX for Predictive Quality

PDX for PDQ is suited for a wide range of industrial sectors. This solution is designed to predict and prevent process issues, as well as ensure high product quality. Early detection enables intervention prior to the production of poor quality parts, allowing for timely corrective actions. This proactive method enhances product quality, prevents unplanned downtime, and diminishes scrap, streamlining operations and controlling costs. It also reduces the need for extraneous final inspections and product testing. PDX for PDQ utilizes a template-based approach to provide pre-configured solutions that can be customized to fit a customer’s specific application, delivering faster configuration and deployment.

Connect

PDX provides connectivity and data acquisition capabilities, including support for a wide range of DAQ devices and protocols, as well as seamless integration with existing databases.

Monitor

PDX provides visualization tools, as well as reporting and alerting capabilities, to ensure that actionable information is delivered to prevent impending downtime or quality issues.

Analyze

PDX uses templates for common industrial assets for the rapid deployment of machine learning and AI models while maintaining the highest detection and prediction accuracy.

VALUE

UP TO

$

2

m

IN SAVINGS

AVERAGE

25

%

DOWNTIME

REDUCTION

AS LITTE AS

1

YR

RETURN ON

INVESTMENT

AVERAGE

$

500

k

ANNUAL

SAVINGS

UP TO

5

%

SCRAP REDUCTION

INDUSTRIES

Predictronics’ customizable and versatile solutions have been deployed in a wide range of industries and applications, enabling businesses to overcome common industrial challenges to reach their full potential.

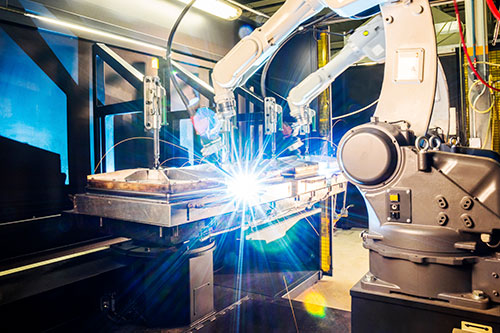

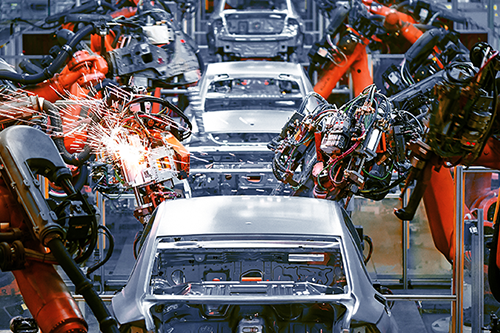

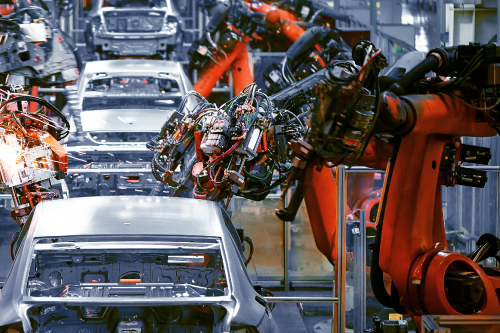

Automotive Manufacturing

With Predictronics’ solutions, automotive suppliers and manufacturers can predict the degradation of critical assets, such as industrial robots and press machines, to prevent unforeseen downtime, extend and optimize maintenance windows, eliminate production line bottlenecks, and reduce product quality issues. This empowers Predictronics’ customers to achieve optimal productivity, avoid wasted resources, reduce warranty claims and recalls, and increase profit margins.

INDUSTRIAL

ROBOT

PRESS

MACHINE

INDUSTRIAL

ROBOT

Predictive solutions help automotive manufacturers avoid machine failures and potentially save $10,000 per minute of production downtime.

LEARN MORE

PRESS

MACHINE

Machine tools, including press machines, have a market growth rate of 7 percent each year. With this increasing demand, companies are relying on predictive maintenance solutions to prevent production stoppage events, which can cost a business tens of thousands of dollars in machine damages and downtime.

LEARN MORE

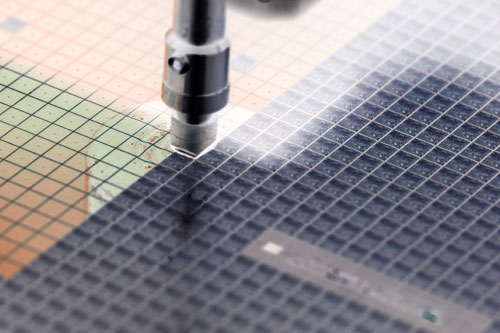

Semiconductor Manufacturing

Predictronics’ predictive solutions enable manufacturers in the semiconductor industry to extend component life through preventative maintenance, reducing wasted resources and avoiding replacement parts and labor costs. Predictronics’ solutions for virtual metrology and chamber matching can also monitor key process parameters that can predict product quality, increasing yield rates and reducing scrap.

| Customer Type | Process | Goal | Solution |

|---|---|---|---|

| Fab (End-User) |

Etching | Component Life Prediction | Predictive Maintenance |

| Etching | Early Fault Detection | Predictive Maintenance | |

| Wafer Slicing | Quality Prediction | Virtual Metrology | |

| CZ Process / Silicon Growing | Quality Improvement | Anomaly Detection | |

| Machine OEM |

Lithography / Stepper | Quality Prediction | Virtual Metrology |

| Etching | Process Optimization | Chamber Matching |

SEMICONDUCTOR

In semiconductor manufacturing, capital equipment loses an average of 8% uptime to unexpected failures and 7% uptime to scheduled maintenance. Predictive solutions improve maintenance efficiency and extend the life of semiconductor equipment components.

LEARN MORE

Process Manufacturing

From food and beverage production and pharmaceuticals to raw material processing and textile fabrication, process manufacturing encompasses a wide variety of industries. By utilizing Predictronics’ predictive solutions, manufacturers can improve process optimization, maintain quality standards, reduce waste and prevent lost profits.

SEMICONDUCTOR

NIPPON STEEL

SEMICONDUCTOR

In semiconductor manufacturing, capital equipment loses an average of 8% uptime to unexpected failures and 7% uptime to scheduled maintenance. Predictive solutions improve maintenance efficiency and extend the life of semiconductor equipment components.

LEARN MORE

STEEL

With more than 90% of steel manufacturers operating with excessive maintenance costs, predictive solutions can minimize production losses and prevent unplanned downtime, reducing the cost per ton and potentially saving companies billions in revenue each year.

LEARN MORE

Discrete Manufacturing

Discrete manufacturing companies, such as those that produce appliances, automobiles, electronics and industrial equipment, among many others, can leverage predictive solutions to improve productivity, reduce downtime, accelerate the assembly process, increase product quality and optimize maintenance planning.

PRESS

MACHINE

Machine tools, including press machines, have a market growth rate of 7 percent each year. With this increasing demand, companies are relying on predictive maintenance solutions to prevent production stoppage events, which can cost a business tens of thousands of dollars in machine damages and downtime.

LEARN MORE

Marine Transportation

In marine vessels, major machinery and component malfunctions, such as diesel engine failures, can cause costly downtime and lost revenue due to shipping delays or missed opportunities. Predictronics’ predictive solutions increase overall reliability, ensure availability, reduce wasted resources and prevent lost profits.

DIESEL

ENGINE

In the marine industry, 68% of vessel failures occur due to unnecessary and invasive maintenance. With predictive solutions, component degradation can be fixed on an as-need basis through preventative maintenance planning, increasing overall marine vessel reliability and preventing unnecessary costs.

LEARN MORE

Automotive Transportation

With Predictronics’ predictive solutions, automotive manufacturers can predict the degradation of components within automobiles to enhance production assembly, detect and diagnose vehicle health issues, improve fleet availability and resource planning. These improvements to the production line increase product quality and safety, optimize fuel economy, and prevent recalls and warranty claims.

AUTOMOTIVE

FLEET

Predictive solutions help automotive companies prevent recalls and improve the quality and safety of vehicles for passengers. On average, the automotive industry sees 906 recalls in a year with 46,000 vehicles affected per recall.

LEARN MORE

Railway Transportation

By monitoring the health of railway systems and predicting failures in railway components, such as platform doors, point machines, induction motors, track tracers and more, companies in the railway transportation industry can optimize preventative maintenance schedules and ultimately address issues before they occur. Preventing these issues will increase customer satisfaction through reduced delays, while also increasing overall safety, efficiency, reliability and availability.

PLATFORM

DOOR

Through predictive solutions, the railroad industry can minimize costly unscheduled maintenance and prevent cargo and passenger delays. This is essential in an industry that spends just under 25 billion U.S. dollars on rail infrastructure and equipment.

LEARN MORE

Aircraft Transportation

Monitoring the health of commercial aircraft and predicting component and subsystem failure before it occurs is essential to keeping passengers safe, maintenance costs low and flights on time.

COMMERCIAL

AIRCRAFT

Predictive solutions help airlines perform preventative maintenance to avoid expensive delays, which can potentially cost airlines an estimated $97 per minute, and prevent flight cancellations, which can potentially cost airlines an average of $68,000 per flight.

LEARN MORE

Oil & Gas

Unexpected failures in the oil and gas industry can cause costly downtime, as well as result in safety risks and hazardous leaks. Through Predictronics’ predictive solutions, oil and gas companies can detect the equipment and machine failures before they occur, increasing productivity, improving safety, reducing overall costs and improving profits.

MUD PUMP

Predictive solutions in the oil and gas industry prevent hazardous leak events, as well as unscheduled downtime due to inefficient maintenance practices that can cost refiners a potential average of $60 billon per year in operating costs.

LEARN MORE

Heating & Air Conditioning

Manufacturers and professionals in the building services industry face consistent challenges when developing, installing, and maintaining systems, such as heating and air-conditioning. With Predictronics’ predictive solutions, these businesses can detect component and subsystem failures before they occur, allowing for planned preventative maintenance, decreasing wasted manpower and reducing operating costs, while also improving uptime and customer satisfaction.

HVAC

EQUIPMENT

Predictive solutions provide the HVAC industry with the intelligence needed to determine component degradation and take preventative maintenance steps, saving companies a potential $22,000 per minute in unexpected downtime due to system failures.

LEARN MORE

Agriculture Equipment

From tractors and combines to planters and balers, farming equipment manufacturers want to provide their customers with high quality machinery through improved overall health and increased uptime. By utilizing data-driven solutions, manufacturers can increase the reliability of their equipment, helping farmers enhance the productivity and efficiency of crop production and reduce machine replacement and repair costs.

AGRICULTURE

EQUIPMENT

Predictive solutions ensure the reliability and efficiency of machinery in agriculture, allowing for proactive maintenance that can potentially save customers anywhere from $8 - $156 an hour per vehicle in fuel, repair, and general costs.

LEARN MORE

Mining Equipment

In the mining industry, underperforming machinery can cause hazardous accidents and lead to production and process issues. With Predictronics’ predictive solutions, industry professionals can pinpoint equipment and vehicle health issues, determine component failure, prevent bottlenecks with proactive maintenance, and improve miner safety.

MINING

EQUIPMENT

In the mining industry, predictive solutions provide businesses with the intelligence they need to make smart maintenance decisions, potentially saving more in lost profits due to fleet vehicle downtime than the earnings from a single mining construction site, with typical costs averaging at about $180,000 per incident.

LEARN MORE

USE CASES

Predictronics has developed over 20 case studies, highlighting our projects with real-world clients in numerous industrial applications. Our solutions bring value to these customers by reducing downtime, optimizing productivity, and improving product quality.

View More

View More

View More

CUSTOMERS

Predictronics has provided solutions to more than 80 businesses worldwide, impacting nearly every industry. Our work brings value to our customers, many of whom are Fortune 500 companies, by preventing failures, reducing unplanned downtime, lowering costs, optimizing productivity, minimizing scrap and waste, and reducing product quality issues.

“With Predictronics, we’re able to monitor the machine health, see real-time how the machine is doing, and start to see a signal of a problem before it becomes a major problem. At this point, I’m really pleased with the progress we’ve made and I’m anxious to expand this solution to our other nine hot forming machines.”

Steve Wright

Maclean-Fogg

“After meeting and interacting with all the various vendors at the National Association of Manufacturers event, I realized I already had all I need in our partnership with Predictronics.”

Peter Dowling

Hino Motors

“Predictronics has a strong technology offering backed by appropriate software licensing prices that work best with our business model, as compared to Predictronics’ competitors.”

Mark Allen

A.O. Smith

View More

“Predictronics’ predictive quality offering complemented and added more value to our in-house quality testing machine. Their AI solution is sophisticated and it provided more granularity on the severity of a defect. These insights would otherwise not have been clearly understood before we deployed this solution.”

Richard Joyner

A.O. Smith

“Predictronics exceled over other competitors in terms of data processing and detection accuracy as well as feasibility, but we were mostly impressed by their distinguished amount of experience.”

Hisashi Asada

Komatsu

“This platform [PDX] helps our customers solve issues that can occur when implementing predictive maintenance solutions, such as the shortage of experienced data analysts and the large financial investment needed to develop a deployment system.”

Dentsu Soken Inc.

View More

“They [Predictronics] offer a unique advantage over other vendors who provide packages with limited solutions. Problems are solved all at once by covering every possible analytic method. This is totally different approach from previous methods. Introducing these new techniques made me I feel like I can finally see light at the end of the tunnel.”

Manabu Inoue

Nippon Steel

RESOURCES

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

INDUSTRIAL AI AND ITS CHALLENGES AT THE 2018 PHM WORKSHOP

Predictronics' Co-Founder, Professor Jay Lee, and CTO, Dr. David Siegel, had a successful Workshop on Industrial AI at the 2018 Prognostics and Health Management Conference, discussing the successes and challenges of industrial artificial intelligence.

View More

View More

View More

View More

View More

ABOUT

PREDICTRONICS HIGHLIGHTS

OVER

15

COMMON

COMPONENTS

OVER

25

ASSET

TEMPLATES

OVER

20

INDUSTRIAL

APPLICATIONS

ISSUES DETECTED

DAYS,

WEEKS OR

MONTHS

BEFORE FAILURES

CAN OCCUR

OVER

70

SUCCESSFUL

DEPLOYMENTS

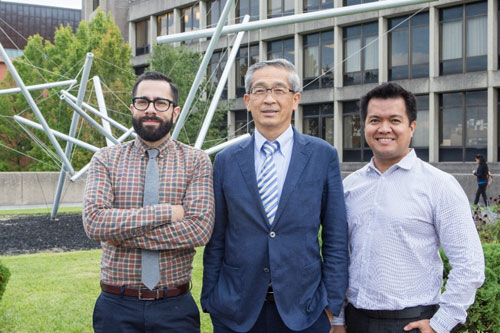

OUR STORY

Predictronics has been at the forefront of bringing Predictive Analytics and AI solutions to the market since 2013. Our company was founded as a startup by senior researchers and developers from a National Science Foundation-funded research center at the University of Cincinnati. We have helped customers in nearly every industry collect and analyze data to monitor critical assets and discover the key to predictive maintenance, predictive quality, and condition-based maintenance. Our solutions have prevented pain points that can quickly add up to millions of dollars in downtime, repairs, and wasted scrap. Predictronics has served more than 80 customers globally and our solutions have been awarded on six occasions by the National Association of Manufacturers.

OUR EXPERTISE

The Predictronics team empowers customers to demystify industrial data and draw actionable insights from it. We want you to take ownership of your process, regardless of skill level, and make more informed decisions to increase productivity and profitability. Our engineers, data scientists, and software developers combine expertise in IIoT, Data Acquisition, Machine Learning, Health Monitoring, Fault Diagnosis, Predictive Analytics, and Industrial AI to deploy solutions that remove the guesswork from production and maintenance planning, replacing it with accurate predictions that allow you to have a worry-free process. We know what happens next, and so can you.

Edzel Lapira, PhD

CEO

Dr. Edzel Lapira is a Co-Founder and the Chief Executive Officer for Predictronics Corp. As the CEO and business lead for Predictronics, Dr. Lapira is responsible for the business development of the company, fostering client relations, and cultivating new leads. He has also overseen the successful integration and deployment of Predictronics’ solutions for over 70 clients. Dr. Lapira has 15+ years of experience working with AI-based predictive solutions, as well as a background in health monitoring and electrical and industrial engineering.

David Siegel, PhD

CTO

Dr. David Siegel is a Co-Founder and the Chief Technology Officer for Predictronics Corp. As Predictronics’ CTO, Dr. Siegel has overseen the development of Predictronics’ end-to-end software platform, PDX, as well as the deployment of predictive maintenance and predictive quality data solutions for over 70 industrial clients. In addition to building the software road map for Predictronics and crafting customized solutions for clients, Dr. Siegel creates new algorithms and methodologies and guides the Predictronics data science team. David has 15+ years of experience working with AI-based predictive solutions and is a well-known leading expert in the Prognostics and Health Management (PHM) community.

Patrick Brown

CFO

Patrick Brown is a Co-Founder and the Chief Revenue Officer for Predictronics Corp. With a diverse background in accounting, design, and client services, as well as experience in promoting predictive solutions for the industrial market, Patrick is uniquely suited to his role at Predictronics where he manages financial matters and aides the leadership team in the execution of numerous key initiatives involving talent recruitment, operations, and business development.

Edzel Lapira, PhD

Board President

Dr. Edzel Lapira is a Co-Founder and the Chief Executive Officer for Predictronics Corp. As the CEO and business lead for Predictronics, Dr. Lapira is responsible for the business development of the company, fostering client relations, and cultivating new leads. He has also overseen the successful integration and deployment of Predictronics’ solutions for over 70 clients. Dr. Lapira has 15+ years of experience working with AI-based predictive solutions, as well as a background in health monitoring and electrical and industrial engineering.

Patrick Brown

Board Secretary

Patrick Brown is a Co-Founder and the Chief Revenue Officer for Predictronics Corp. With a diverse background in accounting, design, and client services, as well as experience in promoting predictive solutions for the industrial market, Patrick is uniquely suited to his role at Predictronics where he manages financial matters and aides the leadership team in the execution of numerous key initiatives involving talent recruitment, operations, and business development.

Kelly Campbell

Board Member

Kelly Campbell was convinced Predictronics would revolutionize the industrial space through predictive analytics. Campbell has helped Predictronics transform their research into real-world impacts by advising and informing company decisions through his business expertise and providing assistance with company expansion, identifying the right talent to join the Predictronics team from the University of Cincinnati’s Center for Intelligent Maintenance Systems (IMS).

With more than 20 years of experience in developing and maintaining client relations, Campbell’s business advice and work securing investments was instrumental to the formation of the company. Campbell is committed to further developing the business and sharing Predictronics’ impact with the world in order to help more customers make informed and strategic data–driven decisions.

Rajesh Narasimhan

Board Member

Mr Rajesh Narasimhan, a Singaporean aged 58 years, is an alumnus of the Indian Institute of Management - Ahmedabad and also holds a Masters in Computer Applications and a Bachelor's Degree in Statistics. He currently serves as the Director and Chief Executive Officer of TVS Digital, a wholly owned subsidiary of TVS Motor Company that is being leveraged to operationalise a digital technology start-up focused on the Automotive and Fintech industries with portfolios & offerings that will deliver high quality solutions and platforms to help address real life business challenges by harnessing the power of exponential technologies including Analytics, Artificial Intelligence (AI), Augmented Reality (AR), Internet of Things (IoT), Machine Learning (ML) and Virtual reality (VR).

Additionally, Mr Narasimhan is also a Non-Executive and Non-Independent Director on the board of Sundaram Clayton Limited and chairs their Stakeholders Relationship committee. He is also the TVS Digital and TVS Motor Company Nominee Director on the boards of several digital start-ups in which they have invested including Altizon Systems, Fabric IoT, Intellicar Telematics, Predictronics Corp. and Scienaptic AI. He has also served as a Non-Executive Independent Director and as a Non - Executive Non-Independent Director on the boards of TVS Motor Company (May 2017 – March 2021) and TVS Motor (Singapore) Pte. Ltd (March 2021 – September 2023) in addition to serving as a Non-Executive Director on the boards of Parrot Solutions Pte. Limited, a Singapore incorporated digital start-up between May 2017 – January 2021 and Tagbox Solutions (both in India and Singapore) between May 2019 – September 2023.

Mr Narasimhan is an Innovative & highly adaptable leader with more than three and a half decades of experience in both start-up and mature organizations across multiple industries including Information Technology, Consumer Durables & Consumer Electronics and brings extensive experience in General Management, Executive & Technology Leadership, Business & Digital Transformation and Leadership & Talent development.

Mr Narasimhan has a successful and credible career track record at various TVS companies, CSC / Covansys (Public listed, US headquartered and a CSC Group Company) and Hewlett Packard, where he has been highly rated and valued as a quality top talent consistently delivering in every role and growing rapidly within the respective organizations. He held several Senior Executive positions at Hewlett Packard where he successfully led multiple business transformations and turnarounds last leading the delivery of their multi-billion $ enterprise services business across 25 countries in Asia Pacific & Japan where he had accountability for over 15,000 employees and more than 400 partners and vendors. Prior to this, he also served as the Vice President & General Manager of the Enterprise Services business in Asia and as Vice President of Hewlett Packard's multi-billion $ Applications services business for Asia Pacific & Japan.

Mr Narasimhan has advised several Fortune 500 clients on their business transformation through digital and technology innovation leveraging Automation, Cloud, Cyber-security, Data Analytics and Management, Mobility & Social and is currently helping the Sundaram Clayton Limited and TVS Motor Company Limited group companies with their Digital Transformation and Cybersecurity initiatives. He is very passionate and highly focused on Human Capital Management including Leadership and Talent development and has an established track record in acquiring, developing and retaining talent and in building high performance teams.

Prior to joining Hewlett Packard in June 2010, Mr Narasimhan had a 15+ year tenure with CSC / Covansys during which he lived and worked in France, the Middle East & Singapore establishing and expanding its business & presence in the Asia Pacific, Japan and the Middle East geography last serving as their Senior Vice President and Head for the geography. Prior to joining CSC / Covansys in January 1994, he held several executive positions with TVS companies in India including at Sundaram-Clayton Ltd., TVS Whirlpool and TVS Electronics.

Jun Naito

Board Member

Patrick Fitzgerald

Senior Software Experience Developer & Designer

Matthew Buzza

Senior Data Scientist

Brian Phillips

PDX DAQ Product Manager & Senior Mechanical Engineer

Aaron Shelly

Senior Data Scientist

Jillian Leedy

Business Development Coordinator & Marketing Manager

Varun Udupa

Solution Engineer

Nathan Moliterno

Solution Engineer

Abhijeet Ainapure

Data Scientist

Shabarish Kesa

Software Engineer

Patrick Brown

Co-Founder

Patrick Brown is a Co-Founder and the Chief Revenue Officer for Predictronics Corp. With a diverse background in accounting, design, and client services, as well as experience in promoting predictive solutions for the industrial market, Patrick is uniquely suited to his role at Predictronics where he manages financial matters and aides the leadership team in the execution of numerous key initiatives involving talent recruitment, operations, and business development.

Kelly Campbell

Co-Founder

Kelly Campbell was convinced Predictronics would revolutionize the industrial space through predictive analytics. Campbell has helped Predictronics transform their research into real-world impacts by advising and informing company decisions through his business expertise and providing assistance with company expansion, identifying the right talent to join the Predictronics team from the University of Cincinnati’s Center for Intelligent Maintenance Systems (IMS).

With more than 20 years of experience in developing and maintaining client relations, Campbell’s business advice and work securing investments was instrumental to the formation of the company. Campbell is committed to further developing the business and sharing Predictronics’ impact with the world in order to help more customers make informed and strategic data–driven decisions.

Edzel Lapira

Co-Founder

Dr. Edzel Lapira is a Co-Founder and the Chief Executive Officer for Predictronics Corp. As the CEO and business lead for Predictronics, Dr. Lapira is responsible for the business development of the company, fostering client relations, and cultivating new leads. He has also overseen the successful integration and deployment of Predictronics’ solutions for over 70 clients. Dr. Lapira has 15+ years of experience working with AI-based predictive solutions, as well as a background in health monitoring and electrical and industrial engineering.

Jay Lee

Co-Founder

Dr. Jay Lee is an Ohio Eminent Scholar, L.W. Scott Alter Chair Professor, Distinguished University Research Professor at the University of Cincinnati, member of the Global Future Council for the World Economic Forum, and the founding director of the National Science Foundation (NSF) Industry/University Cooperative Research Center (I/UCRC) on Intelligent Maintenance Systems (IMS), a world-renowned research center in industrial predictive analytics supported by over 100 global companies.

Dr. Lee’s research focuses on Industrial Big Data, Industrial AI, Predictive Analytics, Prognostics & Health Management and Industry 4.0. In 2013, he facilitated the creation of Predictronics. In addition to serving as a company advisor, Dr. Lee works as an honorary professor at multiple universities, holds several patents and awards, has delivered over 200 keynote speeches and has authored numerous influential books, articles and technical papers.

David Siegel

Co-Founder

Dr. David Siegel is a Co-Founder and the Chief Technology Officer for Predictronics Corp. As Predictronics’ CTO, Dr. Siegel has overseen the development of Predictronics’ end-to-end software platform, PDX, as well as the deployment of predictive maintenance and predictive quality data solutions for over 70 industrial clients. In addition to building the software road map for Predictronics and crafting customized solutions for clients, Dr. Siegel creates new algorithms and methodologies and guides the Predictronics data science team. David has 15+ years of experience working with AI-based predictive solutions and is a well-known leading expert in the Prognostics and Health Management (PHM) community.

CONTACT

Please contact us via email below for any inquiries on how we can help your business succeed!

Contact us!